Sell PVC granules medical grade

PVC granules medical are a special form of plastic molding. Which can be used in a variety of melting and plastic forming machines. Regarding the durability and physical properties of PVC granules, various types of fixtures. And fixtures are used in accordance with various production methods. That enhance or reduce some of its properties.

Recycle Divers and Convert To Granules

Today, with the development and development of the recyclable industry. Since the couplings are 100% complete and fully recyclable, using new technologies and techniques. The recycling of PVC makes it possible to return the waste cycle of this material to the stage of productivity and reuse. The inherent characteristics of the paverion are such that it can play its role in the production of a variety of products, either directly or in combination, after recycling.

Recycle potion of PVC granules medical

There are many ways to open waste today.

Mechanical Recycling:

This process is the common method of recycle recycling. In this type of recycling, after mechanical separation, removing impurities, grinding and washing. Or as a blend in the production of new products, after melting.

The hard type used in the manufacture of pipes and fittings, toys, doors and windows, gutters, gaskets, etc. One of the most important products that comes from the recycling of PVC is the water and sewage pipes. Which are used extensively in the industry. Especially the construction industry, due to their low prices and flexibility.

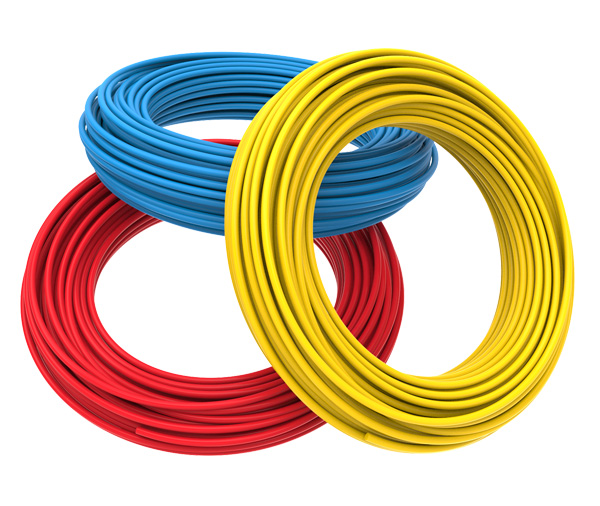

Among other diverse applications, other granular coils can be used to produce electrical wiring insulation coatings. Especially low voltage cables, which are widely used in copper, aluminum and optical fiber wires. As well as being cost-effective against abrasion, and soldering.

New technologies and new laboratory techniques have produced remarkable quality recyclable materials. This quality is so high that the products produced from its recycled materials. The first products, with the same standard and feature, play their part well.

Soft PVC Granule

PVC granules medical make up a wide range of polymeric polymer materials, which in their molecular structure, in addition to carbon and hydrogen, also contain chlorine atoms. This creates unique physical properties in these types of plastics. The temperature that releases these products during burning is lower than that of other plastics. Which makes it more difficult to spread the fire. Other features of PVC are higher density and harder than other plastic types.

This makes PVC products more durable and of high quality. And can be used in higher degradation environments. Along with all this, the availability and affordability of PVC has also increased its use in various products. The soft PVC granule forms a spectrum of PVC that is flexible.

Some applications of soft PVC granules

The raw material for wire and cable:

Due to the chemical and physical resistance and the PVC granules medical insulation properties in conducting electrical current. And temperature shocks create alternating tensile and compression forces. The thermal resistance of these plastics makes the wires and cables made from this polymer more resistant to soldering.

Raw materials Insoles and raw materials Slippers:

The shoe insoles are among the products that are in direct contact with the soil and materials contained therein. On the other hand, the insoles of the foot are exposed at any moment in stretching. Hence, the use of soft PVC granules to produce it can provide acceptable durability for shoes and prevent its early deterioration and deterioration. All of these properties make PVC granules an ideal starting material for slippers.

Raw materials for hoses:

The use of granules to produce hose types is necessary from several directions. Water (as the main substance that flows into the hose) or other chemical and pharmaceutical substances. Including soluble chemicals, which after a while can cause corrosion and rotting of the hose from the inside. On the other hand, hoses are usually exposed to direct sunlight. And should be resistant to cracking due to the need for flexibility. Hence, one of the granular applications is to use it as the primary material for hose types.

The raw material for car roofing:

Car flooring is an elastic plastic plate that covers the floor of the car and makes the car stay healthy and durable. These floors should have a high resistance to a variety of chemicals and given the fact that the cars